Pad Printing Blades

Pad Printing Blades Specification

- Size

- Customized Sizes Available

- Length

- 200 mm to 1000 mm

- Style

- Straight Edge

- Usage

- Ink Transfer / Scraping

- Thickness

- 0.2 mm, 0.3 mm, 0.5 mm

- Type

- Doctor Blade / Scraper

- Application

- Pad Printing Machines

- Dimension (L*W*H)

- 300 mm x 15 mm x 0.3 mm (standard)

- Weight/Volume

- Approx. 100g each

- Material

- Spring Steel or Stainless Steel

- Color

- Silver / Metallic

About Pad Printing Blades

Holding deep knowledge and vast experience in this domain, we are engaged in manufacturing and supplying of Pad Printing Blades. Broadly used for sharp cutting & cleaning of the ink on the roller pads, clients can get these printing blades from us in diverse specifications. Made up of high end quality materials, these printing blades are demanded by diverse industries due to their sharpness, dimensional accuracy and fine finish. Furthermore, we are offering these Pad Printing Blades in quality packing covers.

Range of Steel Printing Blades: 0.5mm to 1.5mm

Some of the salient features of our range of steel printing blades include:

- Accurate dimension

- Durable

- Excellent finish

- Corrosion resistant

- Longer functional life

Superior Construction

Manufactured using premium-grade spring steel or stainless steel, these pad printing blades offer excellent strength, resilience, and wear resistance. The straight edge ensures optimal contact for even ink transfer, boosting print clarity and consistency while maintaining blade integrity through prolonged use. Every blade is finished in a sleek silver or metallic look for a professional touch.

Versatile Applications

Designed for use with pad printing machines, these doctor blades are available in a range of sizes and thicknesses to match diverse requirements. Whether you are printing on industrial parts, promotional items, or electronic components, the blades customizable sizing and robust material make them suitable for various substrates and multiple usage cycles.

FAQs of Pad Printing Blades:

Q: How are these pad printing blades used in the printing process?

A: Pad printing blades act as doctor blades or scrapers to remove excess ink from the surface of the printing plate, allowing only the desired amount of ink to transfer onto the printing pad. This process ensures precision and consistency in each print cycle.Q: What materials are available for these doctor blades?

A: These blades are manufactured from either high-quality spring steel or stainless steel. Both materials provide excellent durability and corrosion resistance, ensuring longevity and reliable performance in challenging printing environments.Q: When should I select a specific blade thickness?

A: Blade thickness (0.2 mm, 0.3 mm, or 0.5 mm) depends on your printing requirements. Thinner blades (0.2 mm) are ideal for delicate or fine-detail work, while thicker blades (0.3 mm or 0.5 mm) are suited for heavier inks or more robust substrates.Q: Where can these printing blades be sourced from?

A: These pad printing blades are available from leading exporters, manufacturers, and suppliers in India. They can be supplied as standard-sized products or customized according to your specific length, width, or thickness needs.Q: What is the manufacturing process for these blades?

A: The production process involves precision cutting of spring steel or stainless steel sheets, followed by edge finishing for a smooth, straight edge. Each blade is inspected for uniformity and quality before packaging to ensure it meets industry standards.Q: How do these blades benefit pad printing operations?

A: Using high-quality pad printing blades ensures a clean, consistent ink transfer, resulting in sharp and accurate prints. Their durable construction reduces the need for frequent replacements, thus lowering operating costs and machine downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pad Printing Machine Accessories Category

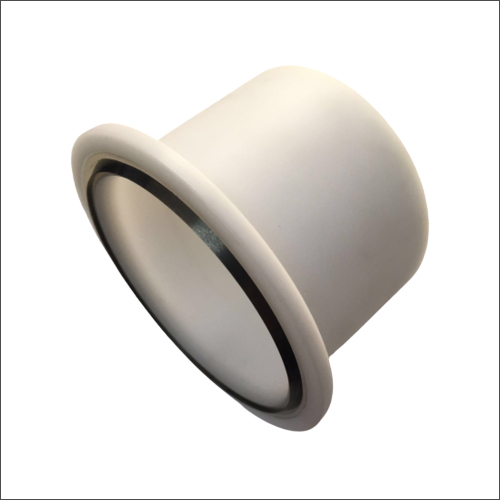

Ink Cup Set Dia 90mm

Price 16500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Size : Dia 90mm

Material : Stainless Steel & Ceramic Ring

Standard : Industrial Grade

Application : Pad Printing Machine

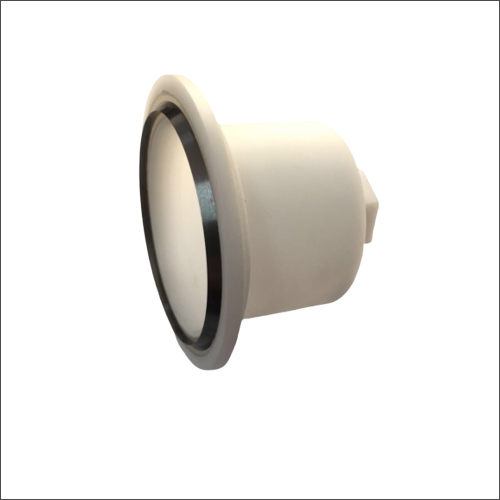

Ink Cup Set Dia 60mm

Price 14500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Size : Dia 60mm

Material : Plastic

Standard : Industry Standard

Application : Pad Printing

Pad Printing Cliche Plates

Price 2800 INR

Minimum Order Quantity : 2 Pieces

Size : Standard & Customized

Material : High Carbon Steel / Stainless Steel

Standard : Industrial Grade

Application : Pad Printing Machinery

Silicone Rubber Printing Pad

Size : Customizable

Material : Silicone Rubber

Standard : Industrial Grade

Application : Pad Printing Machines

Send Inquiry

Send Inquiry Send SMS

Send SMS