Silicone Rubber Printing Pad

Silicone Rubber Printing Pad Specification

- Style

- Rectangular / Custom shapes

- Usage

- Industrial Printing

- Size

- Customizable

- Thickness

- 5 mm to 20 mm

- Standard

- Industrial Grade

- Length

- Up to 200 mm

- Type

- Flat Printing Pad

- Application

- Pad Printing Machines

- Dimension (L*W*H)

- 100 mm x 80 mm x 10 mm (custom sizes available)

- Weight/Volume

- Variable (depends on size)

- Material

- Silicone Rubber

- Color

- Red, Pink, or Transparent

About Silicone Rubber Printing Pad

We follow standard quality measures during the manufacturing and supplying of Silicone Rubber Printing Pad. Made by using supreme quality silicone rubber, these pads can help in smoother and flawless printing. These pads are solvent resistant and accredited among our clients for their excellent quality and durability. Suitable to use in printing industries, we are offering these pads in diverse range. Owing to our best quality of Silicone Rubber Printing Pad, we have gained top-notch repute among our clients.

Key Details:

- Solvent resistant

- Excellent quality

- High durability

- Can help in smoother and flawless printing

Precision Pad Printing for Industrial Needs

Designed for pad printing machines, our silicone rubber pads ensure clear, accurate transfers onto varied substrates. Their exceptional elasticity and surface finish enhance ink release, reducing smudging and improving final print quality. Custom sizing supports unique industrial projects, making these pads ideal for manufacturers seeking reliability.

Customization to Suit Your Specifications

Whether you require standard dimensions or tailored designs, our production capabilities allow for flexibility in shape, thickness, and color. Clients can request custom sizes or styles to fit specialized equipment or specific printing challenges, ensuring optimal compatibility and performance in all printing environments.

FAQs of Silicone Rubber Printing Pad:

Q: How do you use a silicone rubber printing pad in pad printing machines?

A: To use a silicone rubber printing pad, attach it securely to the pad printing machine. The pad picks up ink from an etched plate and transfers it precisely onto the target surface, ensuring a clean and accurate print.Q: What customization options are available for these printing pads?

A: We offer customization of dimensions, thickness (from 5 mm to 20 mm), length (up to 200 mm), color (red, pink, or transparent), and shapes (rectangular or custom-designed) to match specific industrial printing requirements.Q: When should I consider choosing a silicone rubber printing pad for my operation?

A: Silicone rubber printing pads are ideal when you require precise and reliable ink transfer in industrial settings, especially for applications that demand flexibility in shape, size, and chemical resistance.Q: Where can these pads be supplied or exported from?

A: As a manufacturer, exporter, and supplier based in India, we ship silicone rubber printing pads domestically and internationally, accommodating diverse industry needs worldwide.Q: What is the manufacturing process for your printing pads?

A: Our production process involves molding high-grade silicone rubber into desired shapes and sizes, followed by quality checks to ensure uniform thickness, elasticity, and durability suitable for industrial printing.Q: What are the main benefits of using silicone rubber pads for industrial printing?

A: Silicone rubber pads offer excellent ink transfer, durability, and customization. Their non-stick surface improves print definition and longevity, making them suitable for continuous operation and varied substrates.Q: Can I use these pads with all types of pad printing machines?

A: Yes, our flat silicone rubber pads are compatible with most industrial pad printing machines, and custom sizes or shapes can be fabricated to fit specific models or unique applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pad Printing Machine Accessories Category

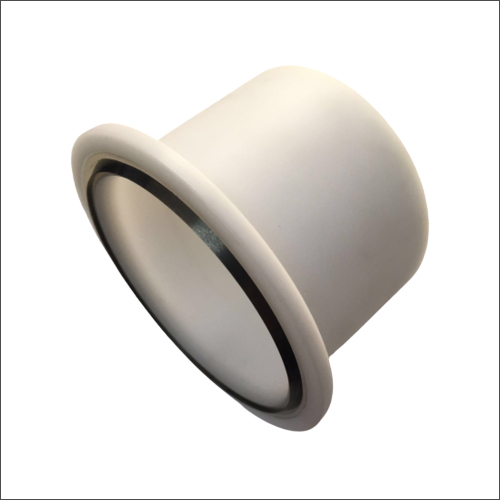

Ink Cup Set Dia 90mm

Price 16500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Silver & White

Dimension (L*W*H) : Diameter 90mm

Type : Other, Magnetic Ink Cup Set

Application : Pad Printing Machine

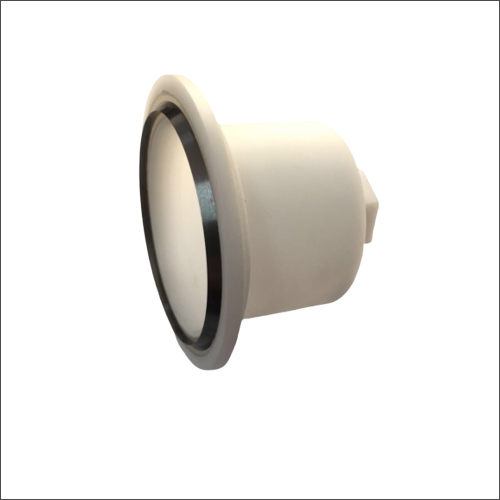

Ink Cup Set Dia 60mm

Price 14500 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : White

Dimension (L*W*H) : 60mm diameter

Type : Cup, Other

Application : Pad Printing

Pad Printing Cliche Plates

Price 2800 INR

Minimum Order Quantity : 2 Pieces

Color : Silver Grey

Dimension (L*W*H) : Standard: 100x215x0.25mm; Custom sizes available

Type : Other, Pad Printing Cliche Plate

Application : Pad Printing Machinery

Pad Printing Blades

Price 235 INR

Minimum Order Quantity : 50 Pieces

Color : Silver / Metallic

Dimension (L*W*H) : 300 mm x 15 mm x 0.3 mm (standard)

Type : Other, Doctor Blade / Scraper

Application : Pad Printing Machines

Send Inquiry

Send Inquiry Send SMS

Send SMS